I was asked to post this old build thread that I did on MIMF. I also posted it on another forum, which is where I have this backup text from. Hopefully it will make sense once you scroll down a bit...

Here’s a new instrument that I’m building. I’m documenting it on MIMF as part of their “$100 Acoustic Challenge”, where you are supposed to build a functional instrument for less than $100, and the one that gets the most votes for their finished instrument wins. As I hate to steer you away from this excellent site, I’m posting it over here as well.

They have a 60 Kb restriction on uploads over there, that’s why the quality of these pictures is so-so. I’m cutting and pasting in most of my text from there too, but I’m cutting out the stuff that is only relevant to the “challenge” etc. I’ll still try to keep the post readable.

Here’s what I wrote:

A local musician asked me this fall if I could build him a Hardanger style arch top mandola, and my first idea for this thing was to make a < $100 prototype for that instrument. Recently he changed his mind however, and he now wants a regular ‘dola instead (honestly, I’m relieved, even if it could have been interesting...). So, I’m still going to build a prototype, but it will be a mandola. I’ve made several madolins over the last few years, but never a mandola, so I’m taking this oportunity to familiarize myself with the instrument.

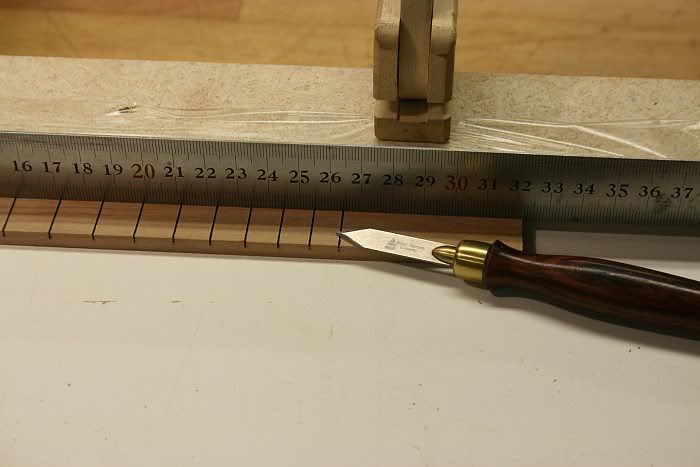

This is an arch top mandolin, Gibson style, more or less. The scale is close to 420 mm (about 16 ½”, I’ll be using a 24,9” fretboard template without the first 6 frets). The body is 300 mm wide, rims 50 mm, oval hole, X-braced.

I’ll be making this instrument solely with Norwegian wood, which is also a first for me. I’ve used local woods in instruments before, but always together with some, or mostly, foreign stuff.

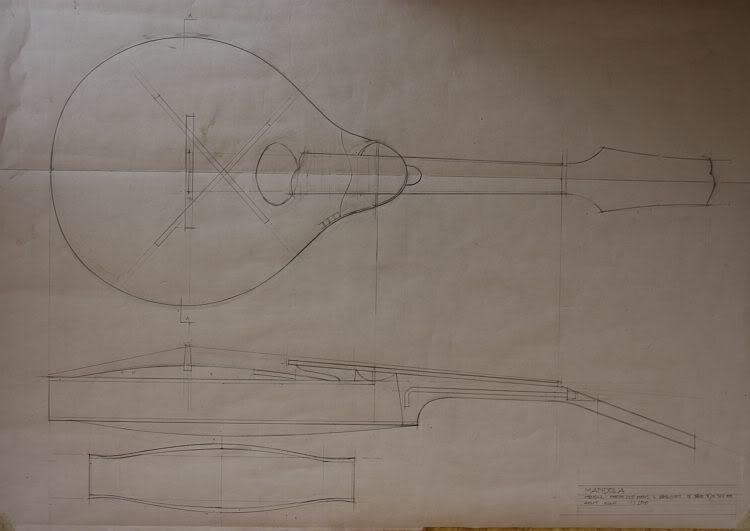

Today I made a plan, templates, prepared most of the woods, glued up the plates, and hopefully I’ll finish the mould and perhaps bend the sides tonight.

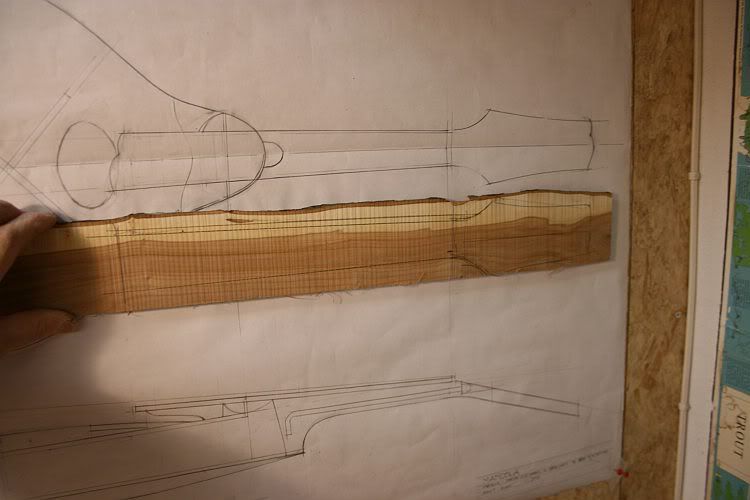

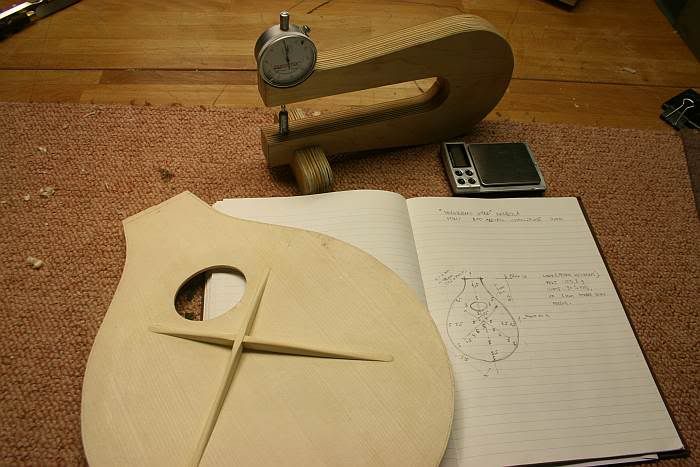

Here’s the plan (I’m an architect and familiar with CAD of course, but for quick stuff like this I prefer to just use pencil and paper if I can).

The back, sides and neck will be birch. I found a 3” board in the reject bin at at a local lumber yard. I just cut sides, backs and neck blanks for 3 mandos from it. The top is spruce, logged right here in my back yard by a local farmer. The fingerboard and perhaps some apointments will be pear. This wood comes from a tree that grew in my pal’s garden, and he gave it to me. I’ll also cut a bridge from it, I think. I haven’d decided if I’m going to use an adjustable truss rod or just carbon fibre. I make my own Gibson style rods and I have nuts from SM. Oh, and I’ll use on of those cheapo, stamped tailpieces.

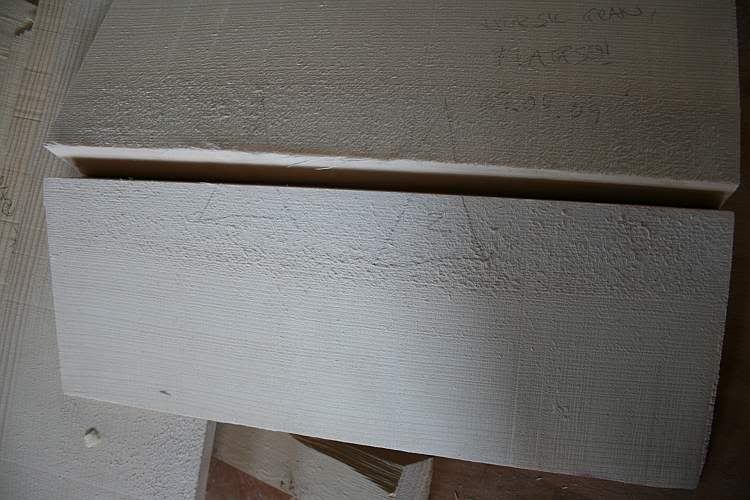

Here’s the birch board with the mandola template this morning (see the date written on the template!).

The wood is nicely flamed throughout, but there are numerous knots, so getting useful pieces out of it proved to be difficult. I did manage to get enough for 3 instruments, but I’m not positive that they will all be withouh knots or blemishes. Oh well!

Here’s on of the spruce bolts.

I cut it into tops that have been drying in my shop since April this year. I prefer to store my wood longer before I use it, but it is nice and dry so I don’t think I’ll have too many

problems.

So, that’s enough chit chat for today, off to the shop!

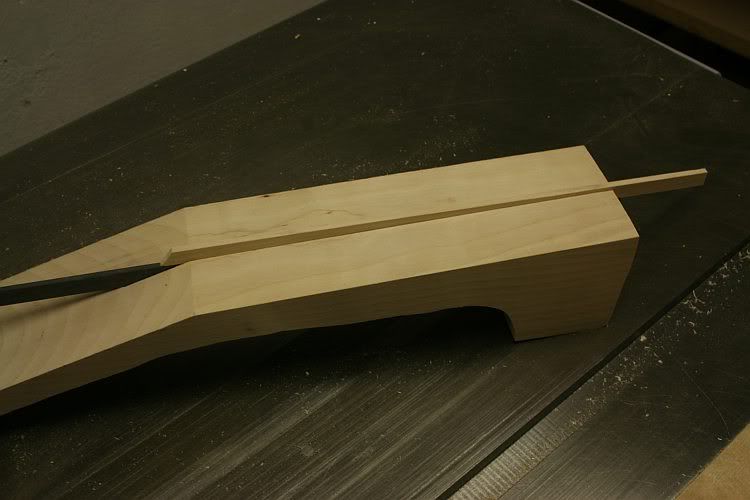

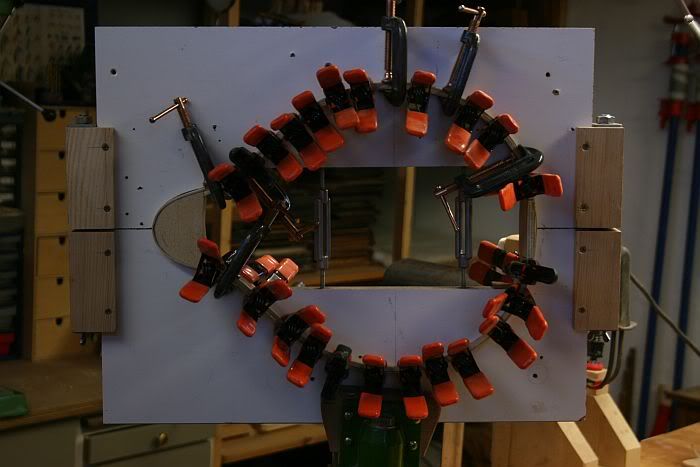

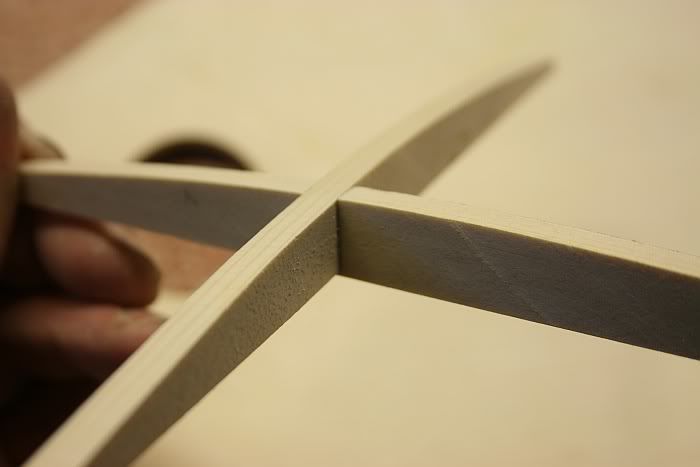

Here’s the rim in the mould, with spruce neck block and plywood tailblock (both from the scrap pile, of course...). Birch is a pleasure to bend, BTW, even if it is fairly flamed, like these were. I used no water except a little right on the neck area, and the sides are 2.2 mm thick. I don’t have a bending jig for mandolin sides, I just use the old steel pipe and torch method.

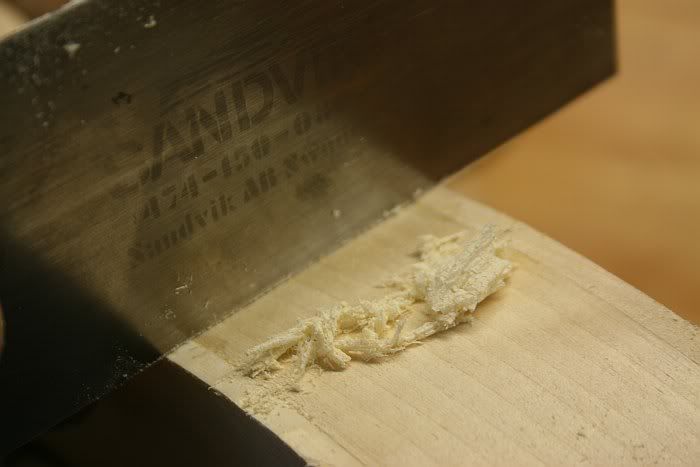

The top was jointed and glued (with hot hide glue) yesterday. Today I trimmed it to size, levelled the bottom and did the router table and Safe-T planer thing on the perimeter, and brought this part down to 5 mm or so. Here I’m beginning to jack plane the rest of the top.

After the rough shaping I use finger planes and finish up with scrapers. For this final part like to use a strong directional light, as it makes it easier to see if all the curves look nice. For this instrument I only made one carving template, the rest of the geometry I just checked quickly against the plan and sort of winged it...

Here’s how it looked after I sanded it

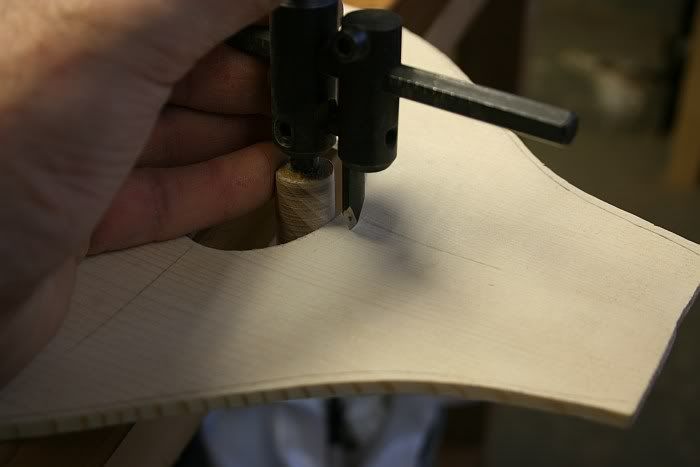

I then put a 15 mm forstener bit in the drill press and mounted a bolt (with a smooth head) directly below it, and set the depth stop to 6 mm. Here’s the result.

I use a carving spoon and finger planes to remove most of the wood. This is my shop made measuring gauge, which is nothing fancy, but it works just fine.

Finally the inside of the top is scraped and sanded smooth.

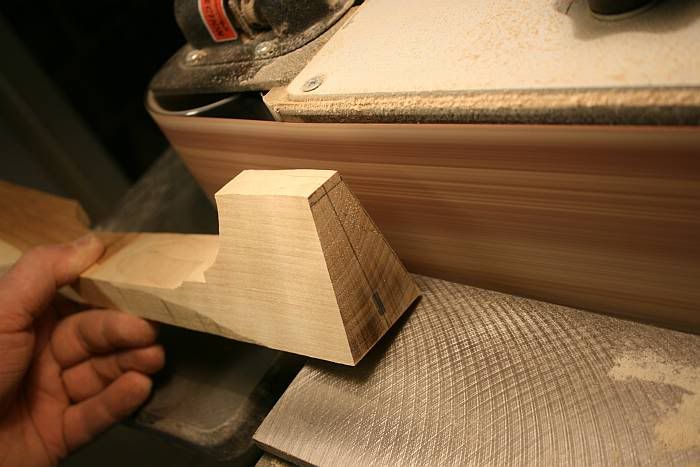

Just had time for a little work on this today, and I decided to work on the back. It was glued up (with hot hide glue) the other day, so today I started by levelling the bottom. This nice old Spiers plane works has no problems smoothing out “difficult” grain such as this.

Like I mentioned in one of the first posts, the birch had quite a few knots and blemishes, but I had cut around most of them. There was one present in this back too, but it was I was pretty sure it wasn’t very deep, and that it would soon be gone when I started carving the outside curves. Wrong! It was much deeper than I had hoped, and as the plate was nearing its final shape, the knot was still very much there. Uh-oh...

Would you look at that!

So, I’m trying to decide if I should join another back, or if I should drench this one with CA glue (or something?) and hope that it does not pop out. I don’t see any signs of it on the inside now, but I’m not sure how deep it is, really.

But perhaps it would look kind of cool, if the instrument is otherwise nicely made. Kinda like that pallet guitar that Taylor made, or Benedetto’s “lumberyard special”. After all, it

i is

supposed to be a prototype, and perhaps in the context of a < $100 instument it would be fitting, somehow.

What do you guys think?